Screen printing has been around for over 100 years

Versatile beyond belief

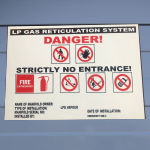

Screen printing is one of the most versatile printing processes. You can almost print on any surface – as long as it is flat. A wide variety of substrates: paper, board, plastics, vinyl, glass, metal, chromodeck, wood, cork, correx & textiles to name a few.

In the screen printing process, ink is pushed through a mesh screen to print a design on the desired material. For each colour within the design or text, a new screen will be used. Screen printing is the deal branding method for a variety of commercial & promotional items.

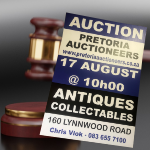

Screen printing is an ideal method for simple designs or text. Artwork with solid colours and isn’t photography based make screen printing the ideal option for logos, graphics & company names. Gradients can also be printed and will have a crisp & sharp design. Screen printing, however, doesn’t lend itself if you are looking to have a design with a wide variety of colour or photography-based design. Spot colours can be mixed with a good degree of accuracy; however, achieving specific shades can be a challenge.

Screen printing is the most cost-effective method if you have to print a lot of products at once. Screen printing has a complex set-up process but usually only need to be set-up once on an order. Some screen printers will even limit the quantities they print. The minimum order quantity on the screen printing is 10 units.